Creating the right conditions: How we customized the cold chain for a specialty customer

January 19, 2026

Case Study Snapshot

Challenges Addressed

- Facility compliance

- Cold storage capacity

- Hazmat certifications

- Specialty team training

Overview

After a customer identified the need for a new cold storage provider who could handle their unique products’ needs, they came to Lineage for specialty cold storage warehousing and transportation.

Can your logistics provider handle it? Lineage can.

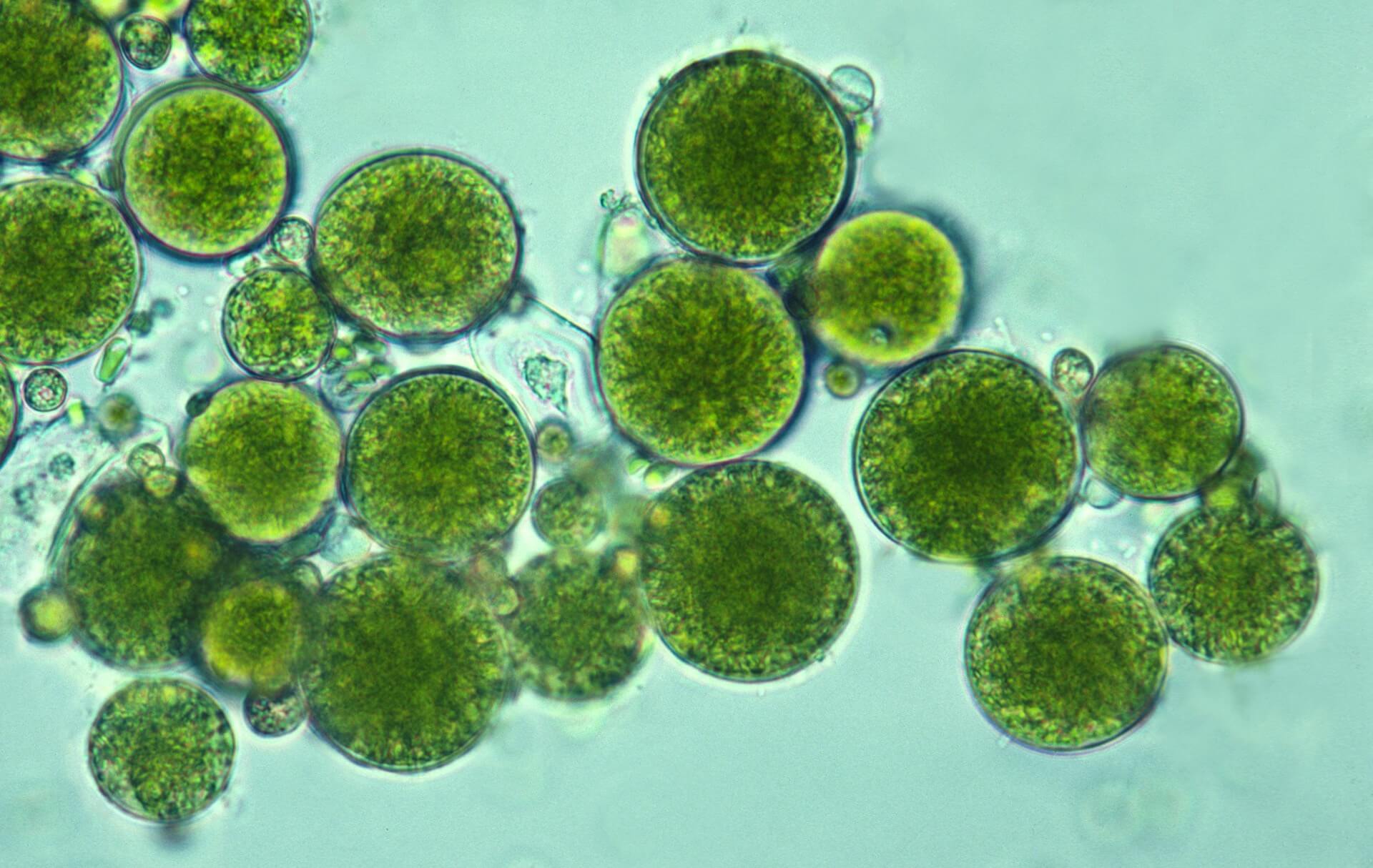

Some commodities require more than standard cold storage solutions. A global leader in health, nutrition and bioscience realized their hazmat-classified algal oils and biomass needed a specialty cold storage solution. With their sights set on a new cold storage provider—one that can handle unique materials with precision and compliance—they turned to Lineage.

Unique commodities bring unique challenges

Algal oil and algal biomass are considered Class 4 Hazmat products. How they’re stored, moved and operated requires following a strict set of safety protocols. To learn the ins and outs of handling our customer’s specialty products, we visited their site for a full download. We gathered detailed information for each product, including:

Algal oil and algal biomass are considered Class 4 Hazmat products. How they’re stored, moved and operated requires following a strict set of safety protocols. To learn the ins and outs of handling our customer’s specialty products, we visited their site for a full download. We gathered detailed information for each product, including:

- Hazmat classifications

- Storage temperature

- Proper handling procedures

- Packaging specifications

- Cleaning products and procedures

From there, we started bringing our own facility into compliance. Safety plans, staff trainings, coordination with the local safety department and waste management services and getting up to speed with regulatory practices all had to happen—without delaying or disrupting the customer’s daily operations.

The race to certification

We selected our Charleston cold storage facility as the most strategic location for the customer’s products, storage and transportation needs. This kicked off an ambitious four-month timeline to achieve certification as quickly as possible.

The timeline:

November

- Customer toured Charleston facility for a site inspection

- Lineage reviewed safety data sheets for potential hazards, safety procedures and regulations

December

- Lineage toured the customer’s production facility to learn proper materials handling

- Lineage developed a Hazard Analysis and Critical Control Points (HACCP) plan and identify steps for preventing or mitigating safety hazards

- The customer’s auditor approved our selected facility

- Lineage registered with the local fire department and waste management

January

- The customer’s product arrived at our facility

- Lineage began ongoing 24-hour Hazardous Waste Operations and Emergency Response (HAZWOPER) training

- Local fire department inspected algal storage

- Safety team reviewed work instructions and provided support and guidance for Safety Data Sheet (SDS) documentation, the development of HACCP plans and the creation of Standard Work Instructions (SWIs)

- Quality Assurance Manager verified team members are properly trained and that proper procedures were followed

February

- Lineage received International Maritime Dangerous Goods and Department of Transportation certification

- Local fire department approved our Charleston site

- Yearly HAZWOPER refresher training scheduled

Signed, sealed, seamless integration

The move goes off without a hitch. Today, our Charleston facility is home to 3,400 pallets of the customer’s product—complete with its own dedicated section, serviced by a fully trained staff.

Complexity, meet customized cold chain capabilities

Not all commodities are stored the same. Lineage is built for meeting the needs of our customers to every degree of specificity. From algal biomass logistics to streamlining cold chain compliance, we have the people, expertise and resources at the ready to help safeguard even the most particular commodities.