The 7 cold chain services every food importer to the U.S. needs to stay compliant and competitive

November 20, 2025

Importing food into the U.S. isn’t simple. Every shipment moves through a maze of regulations, inspections, temperature requirements, carrier schedules and changing tariff rules, not to mention any slowdown at the ports can ripple through the entire supply chain. But U.S. food importers don’t have time for surprises. They need a process that works for them, and Lineage has the end-to-end solutions to help.

From early planning and Harmonized Tariff Schedule (HTS) classification to inspections, bonded storage, drayage and advanced visibility, Lineage brings all the critical pieces together to help keep food safe, compliant and moving.

These are the seven services that matter most for U.S. food importers and why having them connected under one roof helps keep your global supply chain resilient and competitive.

1. Port-centric warehousing: keep imports moving from dock to destination

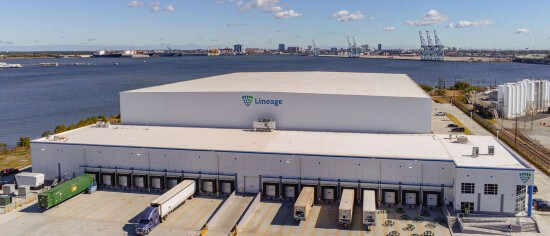

Port congestion and slow unloading are two of the biggest threats to imported food in the U.S. Lineage’s port-centric warehouses help solve both. With facilities positioned near major entry points, cargo can be unloaded faster, inspected sooner and transported under temperature control without unnecessary dwell time.

Port congestion and slow unloading are two of the biggest threats to imported food in the U.S. Lineage’s port-centric warehouses help solve both. With facilities positioned near major entry points, cargo can be unloaded faster, inspected sooner and transported under temperature control without unnecessary dwell time.

That proximity helps importers avoid detention and demurrage, stay on schedule and protect product integrity, especially during peak seasons or when navigating port disruptions.

2. Customs brokerage: clarity and control at the border

Customs is another area where the process can stall. Sometimes it’s over something as small as the wrong HTS code or a missing line on an entry form, but delays and confusion can quickly compound. Lineage’s customs brokerage team looks at those details early, long before the container lands at the port. They review classifications, filings and tariff details upfront, so importers aren’t blindsided later.

Because the team monitors policy changes as they happen—bond limits tightening, new executive orders, shifting quota schedules, updated Customs & Border Protection (CBP) guidance—they can flag them before they become problems. That early warning gives U.S. importers time to adjust and keeps cargo moving.

3. Bonded warehousing: a buffer during trade uncertainty

Tariff and quota changes can throw a wrench in the best-laid plans. When the market shifts mid-voyage, bonded warehousing gives U.S. importers room to adjust instead of rushing product into the system. Lineage’s North American bonded warehouses—located across America and Canada, and operated under CBP oversight—act as a duty-free parking lot for goods until customers decide how and when to release them.

Space in these facilities is limited and used strategically and with purpose. Importers lean on it to bridge quota resets, avoid paying duties before they have to or hold inventory during moments of tariff uncertainty. They’re a pressure valve that keeps the supply chain steady when policies swing or the market shifts.

4. Drayage: the short haul that keeps your shipments on schedule

Import timelines are most fragile in the first few miles. That’s why drayage matters. Drayage moves incoming containers from the port to a nearby cold storage facility to help U.S. importers avoid delays, fees and lapses in temperature control. Lineage’s local dray teams handle the handoff from port or rail to nearby Lineage facilities, helping keep containers moving before delays turn into extra fees.

Import timelines are most fragile in the first few miles. That’s why drayage matters. Drayage moves incoming containers from the port to a nearby cold storage facility to help U.S. importers avoid delays, fees and lapses in temperature control. Lineage’s local dray teams handle the handoff from port or rail to nearby Lineage facilities, helping keep containers moving before delays turn into extra fees.

Because the teams work in the same markets as the ports they serve, they can pivot fast, whether it’s port congestion, a chassis issue or a reefer that needs to be pulled immediately. They simplify the complex: keeping the cold chain running, reducing dwell times and helping prevent per-diem charges from piling up.

5. Freight forwarding: coordinated from dock to door

Importing food into the U.S. requires tracking vessels, shipment schedules and product, and most companies don’t have the time or the expertise for that. Lineage’s freight forwarding team manages the pieces so you don’t have to. The team handles the inbound ocean freight, from booking space and working with carriers to handling reefer requirements and timing.

They also stay in communication with the brokerage, drayage and warehousing teams. This coordination helps importers avoid gaps between arrival, clearance and transport to a cold storage warehouse.

6. USDA I-House inspections: compliance without the wait

Meat and poultry can’t move forward until they clear USDA inspection, and that step can stall a shipment if it isn’t handled well. Lineage’s network of 42 USDA-approved I-Houses in the U.S. brings the inspection process into a controlled environment and works directly with brokerage and drayage teams.

Because those teams work together from the start, containers move off the dock quickly, inspections stay on schedule and your product spends less time sitting in temperature-sensitive limbo. Lineage provides a faster, cleaner path through a required checkpoint.

7. Track visibility with real-time insights you can act on

Once product is moving through Lineage-managed steps and warehouses in the U.S., importers can use the customer-facing portal to follow key milestones and keep track of their shipments. Documents and status details live in one place, making it easier to confirm what steps are completed and what comes next.

Instead of playing phone tag to piece together updates from different teams, food importers get a clear view of their cargo and quick notices if something needs attention.

Stay ahead of trade shifts with the right cold chain partner

Tariffs, quota changes and shifting port conditions can change an import plan overnight. U.S. importers who stay ahead of those changes have a clear advantage, and that’s where Lineage’s mix of cold chain operations, brokerage expertise and port-side positioning matters the most.

With the right partner tracking what’s coming and guiding the next steps, food importers can plan ahead and make adjustments in real-time instead of scrambling at the last minute.