How Lineage puts Lean principles into practice

February 11, 2026

Case Study Snapshot

Efficiencies gained

- Faster truck turn times

- Higher pallet throughput

- More appointment availability

- Sustained order accuracy

Overview

As stewards of the cold chain, we’ve implemented processes that make this vital industry as efficient as it can be. In turn, our Lean practices ladder up to outsized outcomes for our customers across their own supply chains.

Every second and movement matters

In the global food supply chain, even the smallest efficiency can ladder up to significant benefits. Across our warehouses, we optimize every footstep, keystroke and pallet position. Every second we can shave off in our operations directly translates to better speed to market, shorter lead times and boosted efficiencies for our customers.

Efficiency doesn’t happen overnight

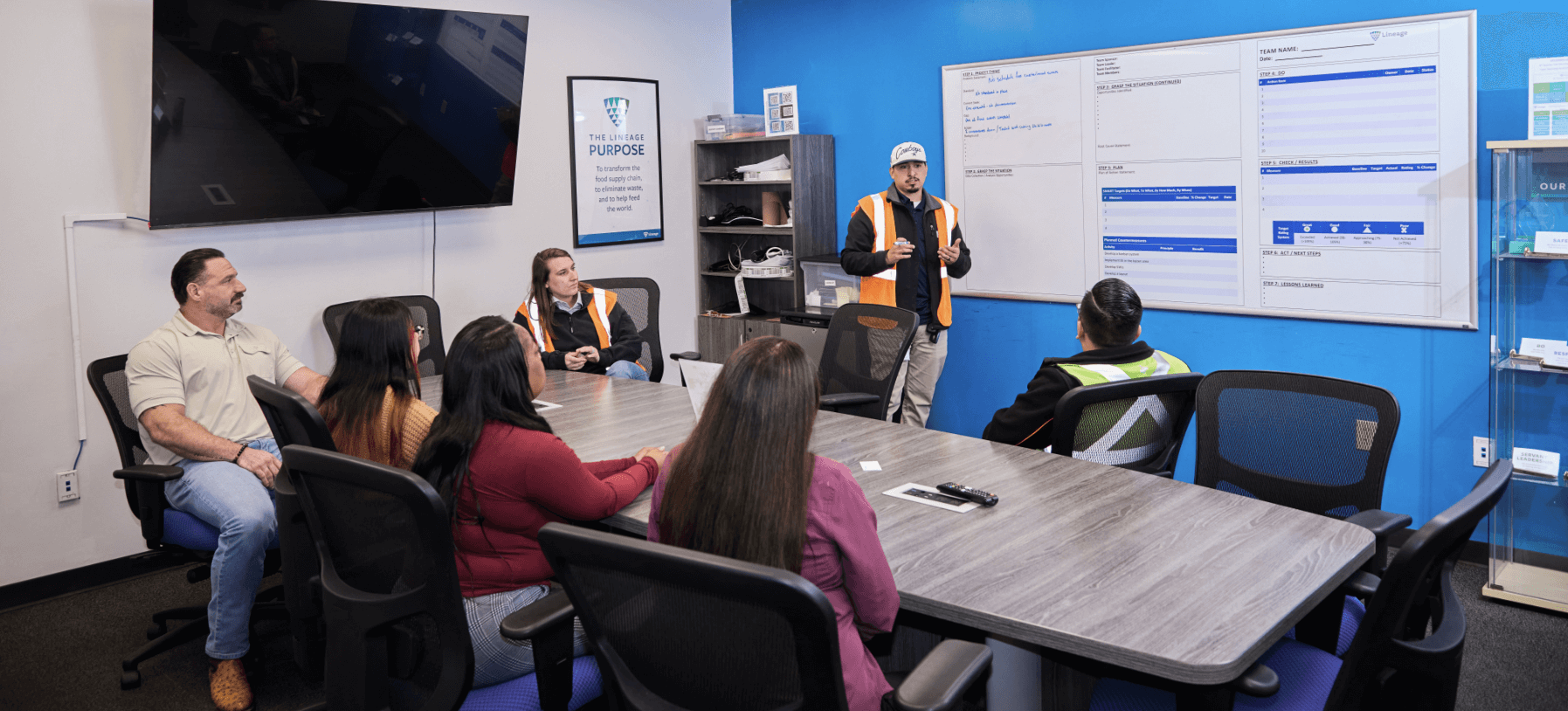

It’s a continuous journey, sustained by a culture rooted in consistent processes and empowered teams. We’ve given our global team a common language to share best practices, identify root causes, problem-solve collaboratively and drive results across our network. Among these efforts is our adoption of Lean, a widely used operational practice geared toward eliminating waste—tailored to solving the cold chain’s unique challenges.

It’s a continuous journey, sustained by a culture rooted in consistent processes and empowered teams. We’ve given our global team a common language to share best practices, identify root causes, problem-solve collaboratively and drive results across our network. Among these efforts is our adoption of Lean, a widely used operational practice geared toward eliminating waste—tailored to solving the cold chain’s unique challenges.

Lean done the Lineage way

We’ve adopted this methodology with a sharp focus on safety, quality, delivery and cost control. The process for Lean certification is rigorous, with all facilities starting at an awareness level before they progress to bronze as the foundational level. There are five levels to certification:

- Bronze

- Silver

- Gold

- Platinum

- Diamond

Each warehouse must meet increasingly strict goals as they progress through the certification process. Currently, 80 global Lineage warehouses are on their Lean journey.

Lean facility spotlight: Fort-Worth Gold Spike

Our Fort Worth-Gold Spike facility has become a model for efficiency and the first to achieve our Diamond-level Lean certification. Since the start of their journey in 2017, the Fort Worth team has achieved:

Our Fort Worth-Gold Spike facility has become a model for efficiency and the first to achieve our Diamond-level Lean certification. Since the start of their journey in 2017, the Fort Worth team has achieved:

- A 47% increase in truck turns

- An increase in outbound JIT loads by 11x in the last two years

- An increase in the number of inbound JIT loads by 55x

- Inbound truck processing time drop from 117 minutes to 22 minutes

- Less dock congestion

- 99% inventory accuracy

Lean in action

Warehouses are all about hustle. We want to get pallets onto trucks as soon as they arrive, but staging product on loading docks causes congestion. To keep product moving more efficiently, we implemented a Just-in-Time (JIT) initiative. Instead of storing product at the docks in anticipation of a truck, we pull items from the freezer right when the truck arrives. Pallets are then loaded directly into the truck, boosting productivity and ensuring timely turns.

Our commitment to improvement doesn’t stop in our warehouses. One of our customers had labels that required hand keying of item codes, quantity and best by dates for every pallet. This left room for human error. We worked with the customer to create advanced labels and pallet identification codes that reduced error and streamlined the process.

The mindset behind momentous impact

Since beginning our Lean journey, Lineage has purposefully built the foundation for lasting improvement and the launchpad for our customers’ own efficiency journeys. Our culture equips our teams with the tools, processes and mindsets to transform cold chain challenges into actionable results.