The science behind smarter supply chains: How one Lineage analysis found $2 million in annual savings

October 24, 2025

Case Study Snapshot

Challenges Addressed

- Capacity issues

- Supply chain bottlenecks

- Supply chain network inefficiencies

Overview

After a customer experienced capacity issues in key areas within their supply chain, they turned to Lineage for a distribution and facility network design to build in new efficiencies.

Your data holds hidden potential

There’s no room for inefficiencies in the global food supply chain. A major U.S. importer called on Lineage for a solution that addressed their challenges now and could scale up with them in the future. But before we could solve for both, we needed to do a deep dive into what our customer was up against, weighing their unique needs against our network and suite of supply chain solutions.

There’s no room for inefficiencies in the global food supply chain. A major U.S. importer called on Lineage for a solution that addressed their challenges now and could scale up with them in the future. But before we could solve for both, we needed to do a deep dive into what our customer was up against, weighing their unique needs against our network and suite of supply chain solutions.

Battling bottlenecks

Capacity issues in the Northeast created bottlenecks at critical points within our customer’s supply chain. This wasn’t just a headache for their current operations, but a potential hinderance for their future growth projections.

They asked Lineage to examine their data and explore new solutions—including the possibility for a new market expansion—that would reduce bottlenecks now and streamline their supply chain for the future.

No data point left unturned

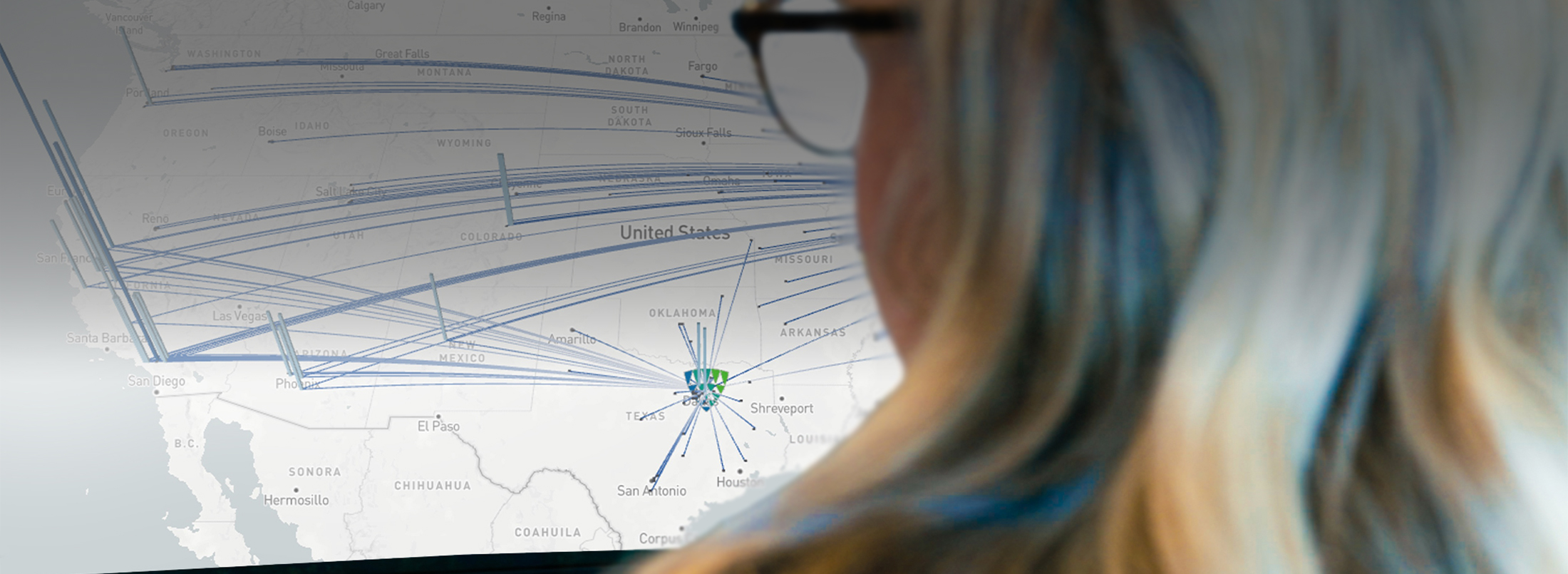

Our in-house data science team got to work. These experts in data, mathematics, engineering and more innovation-forward disciplines apply a unique methodology to conduct in-depth supply chain analyses. For this specific customer, we performed a transportation and facility analysis using the following:

- Historical shipment data

- Supplier and retailer locations

- Transportation rates

- Manufacturing locations

- Warehouse locations

- Ports of entry or departure

This analysis helped them identify appropriate distribution centers to deploy inventory and freight lanes that enable efficiencies across the customer’s supply chain—from production facilities and points of entry to retail shelves.

From analysis to $2 million in annual transportation cost savings

Our team discovered that expanding into four distribution centers and new markets with more capacity would significantly drive down the customer’s annual transportation costs. Additionally, we recommended new ports of discharge with new distribution center locations. These would put the customer’s inventory closer to their product’s final destination and into key markets with more capacity.

Our team discovered that expanding into four distribution centers and new markets with more capacity would significantly drive down the customer’s annual transportation costs. Additionally, we recommended new ports of discharge with new distribution center locations. These would put the customer’s inventory closer to their product’s final destination and into key markets with more capacity.

This move could relieve the customer’s bottlenecks, improve delivery service levels and lower transportation costs by $2 million annually.

Unique challenges call for unique solutions

No two supply chains are the same. That’s why we’ve built a method of network analysis that identifies opportunities, addresses bottlenecks and executes on the evolving challenges your cold chain faces.

If you’re looking for new automation builds, our Greenfield Analysis pinpoints the best locations for a new, automated facility based on your supply chain.

If keeping your inventory consistent is keeping you up at night, our Inventory Forecasting predicts market demand and places your inventory to maintain business continuity without disruptions during seasonal peaks and surges in business growth.

There’s always room to streamline distribution. Our Optimal Facility Location Analysis pairs your data with our network to find the most strategic locations to deploy your inventory.

Efficiency is the name of the game in the global food supply chain. Our Transportation Network Optimization Analysis identifies the best distribution center locations, modes and packing solutions to optimize efficiencies—from production facilities to retail shelves.

Turn data points into power with Lineage

Time is money in the global food supply chain. Lineage can help you make every second count with analysis-driven solutions that build up to a smarter and more resilient supply chain now and in the future.