#}

#}

Smarter, faster supply chains built on data and real-world insight

Smarter, faster supply chains built on data and real-world insight

End-to-end modeling and optimization for the cold chain

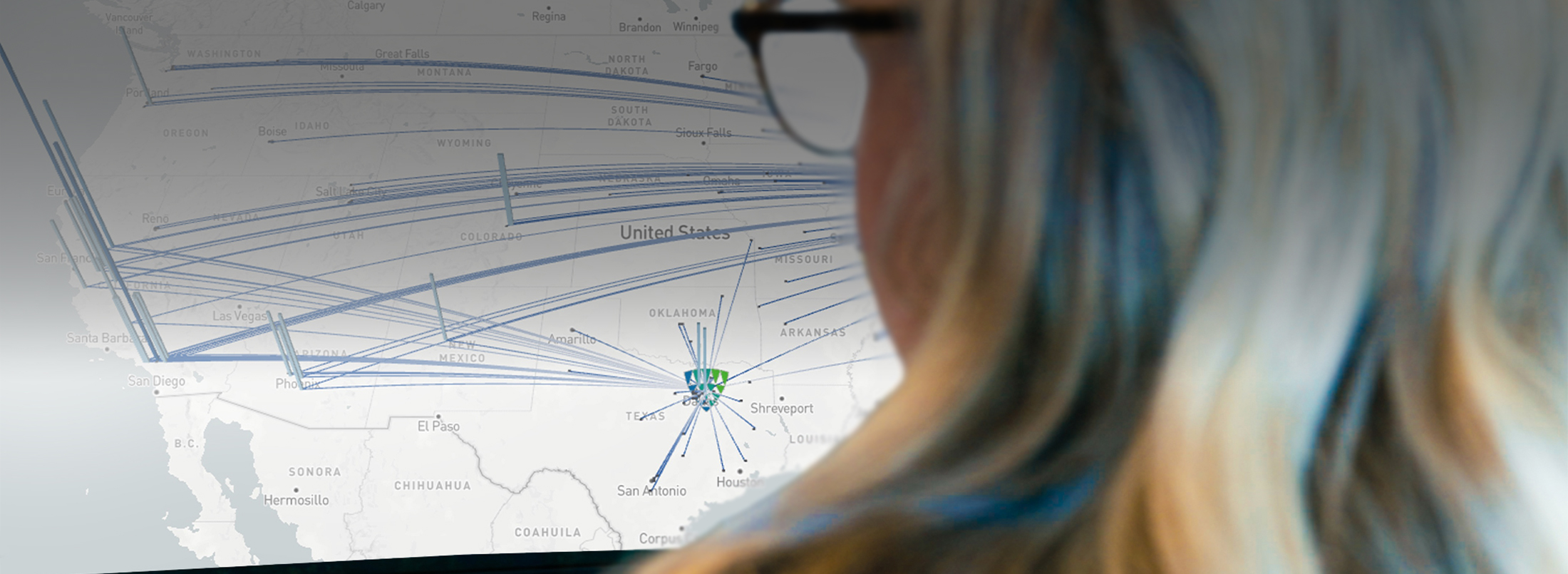

Building a stronger supply chain starts with understanding how all the pieces fit together—your facilities, transportation network, inventory, demand patterns and even the way pallets move inside a building. Our team looks at the whole picture and helps you shape a system that runs with less friction and more confidence.

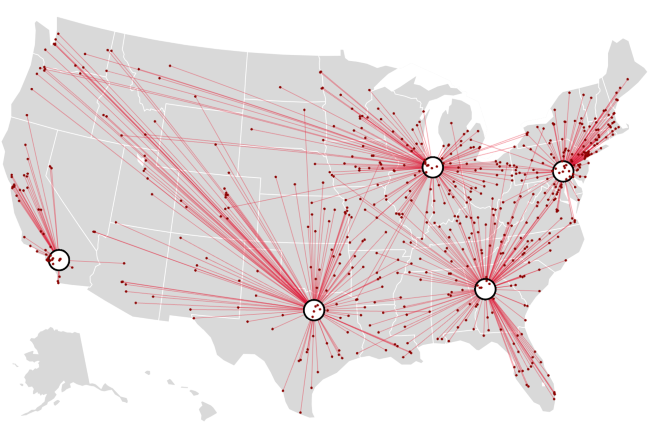

Network modeling & design

A clear look at the best distribution & storage footprint for your products.

Inventory optimization

Stock levels that match your needs without tying up space or capital.

Transportation efficiency

Smarter routing and loading patterns to cut miles and reduce congestion.

Visibility & decision support

Reports and insights that help you make confident, timely decisions.

A partner that can execute the plan

We don’t just model the network, we help operate the one you choose.

A smarter supply chain starts with data and the people behind it

Strong systems don’t come from guesswork. They come from real data and people who know how to read it—and who’ve spent enough time in cold storage operations to know what works in practice.

Our engineers, analysts, modelers and data scientists take on questions like:

- What is the ideal warehousing footprint for my business?

- How can we reduce miles without slowing service?

- What are our biggest network inefficiencies, and how can we fix them?

A few things that set our team apart:

- More than 50 specialists working in modeling, optimization and data science

- A proven approach tested through real customer projects and measurable results

- Clear insight into how your current flows and constraints shape performance

- We take a comprehensive and neutral view of our customers' supply chain network to determine the ideal number and location of facilities to minimize transportation and inventory costs

Why choose Lineage to optimize your supply chain

Innovation with purpose

Our tools and patents weren’t built in a lab—they were shaped on real docks and warehouse floors.

Insights you can use anywhere

One model can inform multiple regions and distribution strategies.

A full-chain perspective

We look at storage, transport, ports, inventory, flow, labor and automation together.

Results you can measure

Get the most out of your supply chain

Smart solutions for complex supply chain challenges

Food shippers and producers come to us with all kinds of challenges; some obvious, some hiding in day-to-day operations. Here’s how we help untangle a few of the most common ones.

Frequently asked questions about supply chain engineering

-

A structured way of examining your full supply chain—facilities, transport, inventory and flow—and improving how they work together.

-

Shipment history, demand patterns, inventory data, facility locations and transportation rates. The data will come from a combination of customer, Lineage and third-party systems and Lineage is happy to assist in collecting it.

-

Yes. Network modeling and facility location analysis are core parts of our work.

-

Lineage Link® gives you real-time visibility into inventory and shipments, making it easier to monitor how your network performs once the new plan is in place.

-

Absolutely. Smaller shippers often see quick wins with routing, flow and inventory planning.

-

A short conversation with your sales managers or account managers and a review of your available data is usually all it takes to start iterating on your custom network solution.

Better clarity on where facilities should be—and why.

More reliable stocking levels to avoid moments of insufficient inventory and unnecessary overages.

Improved routing, loading and lane strategies.

Cleaner movement inside the building and fewer backups.

A safe way to test ideas before investing in them.

Straightforward reporting that make the outcomes clear.

Where supply chain engineering connects with the rest of your operations

-

Cold Storage Warehousing

Placement and flow inside temperature-controlled space.

-

Foodservice Solutions

Cold storage and transportation solutions built for foodservice supply chains.

-

Port-Centric Warehousing

Strategies built around key entry and exit points.

-

Automation & Technology

Tools that make the plan easier to execute at scale.